In today’s ever competitive market we understand that as well as commercial aspects, business is won and lost on manufacturing lead time.

Processing your order with us is fast and efficient, with dedicated production planners using the latest CAD/CAM software. Interactive nesting results in greater material utilisation, productivity and therefore reduced component costs.

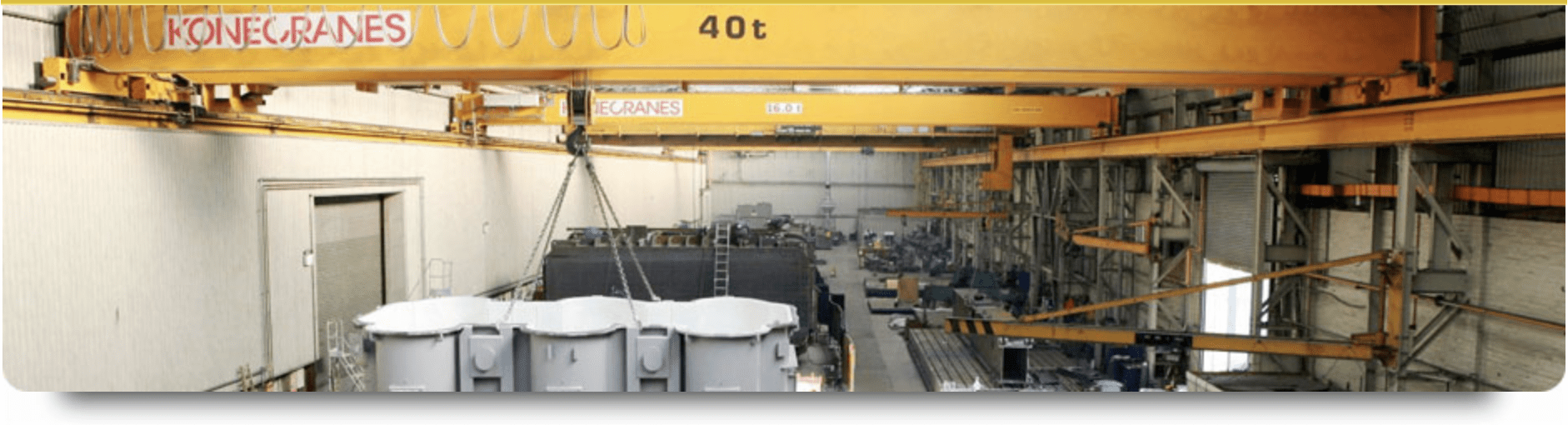

We specialise in bespoke fabrications to your exact requirements. For this reason our machining requirements vary from the smallest boss right up to 77 tonne generator stator frames.

For this reason we have forged partnerships with specific specialist machinists which enable us to offer a “one stop shop” ensuring the most suitable machine processes are adopted.